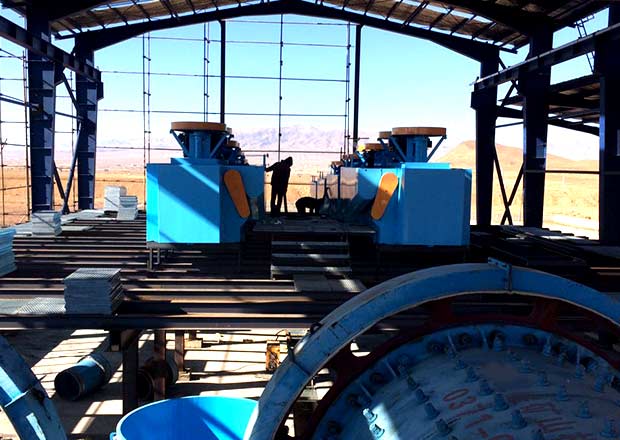

SF Flotation machine is mainly used for the selecting of non-ferrous metals like gold, copper, zinc, etc. It can also be used for coarse and fine selection of ferrous and nonmetals. It is suitable for the materials like gold ore, copper ore, quartz stone, and aluminum ore, etc.

Unique Structure Operation Cost Is Low

1. High flotation efficiency and low energy consumption.

2. No running parts in flotation machine, easy maintenance and overhaul, and long service life of the wearing parts.

3. Mechanical mixing, simple operation and control, high degree of automation.

Easy Operation High Degree Of Automation

In the process of flotation, the pulp after treatment by adding agentia, with stirring and air inflation, some of the mineral particles are selectively fixed on the bubble, and float to the surface of the pulp, being scraped to form foam product. The rest is remained in the pulp to achieve the purpose of separating the minerals.