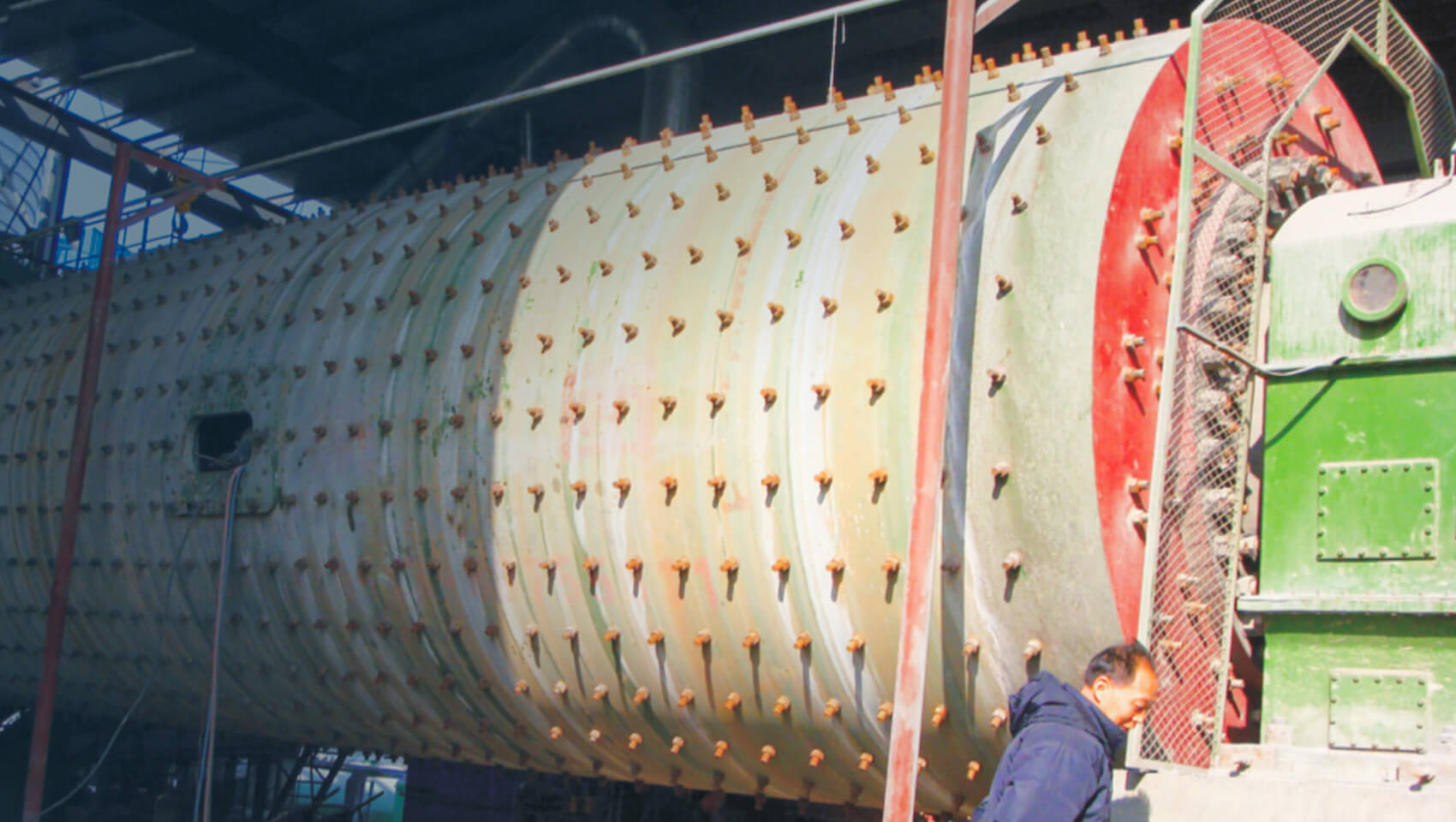

Raw material mill is the critical equipment for re-crushing material that has been crushed and batched by crusher machine. It is the indispensable grinding equipment in cement production process. Raw material mill can be widely used in the industry of cement, silicate product, new building material, refractory material, glass and ceramics production. It can grind all kinds of ores and other grindable materials.

Unique structure

1. High grinding efficiency. The raw material mill has the single silo structure. The inside lining board of mill is designed in combination. Users can choose the linings with different structures according to different grinding stages of raw material, so as to reach the high grinding efficiency.

2. Less investment and higher returns. The raw material mill produced by HXJQ needs low investment, which is less than 35~50% of traditional similar-scale traditional process equipment. What's more, it can meet the material supply of 250 ~ 2500 t/d cement production line.

Easy operation

After a long period of exploration and summarization in the design and production process, HXJQ has manufactured a series of raw material mill products with different specifications, different functional requirements, and rich variety. Especially in the grinding of ore slag and cement, we have more prominent advantages.