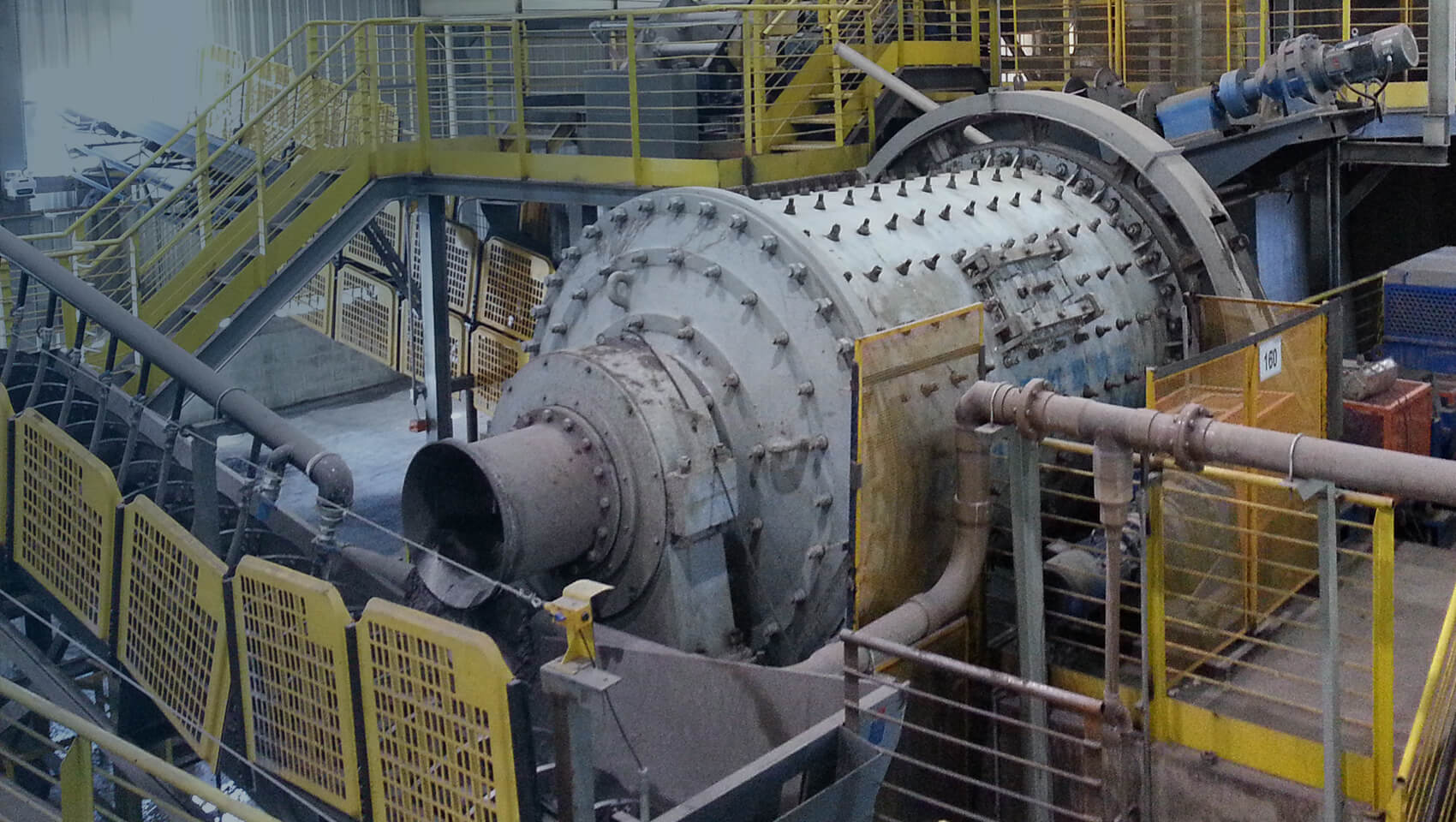

This rod mill can be used as an open-circuit grinding mill, which is widely used in mineral processing, building materials, chemicals, refractory materials and other industries as well as the grinding operations which has higher requirements of finished products uniformity. It is also widely used in the construction sand production industry in recent years. At present, it is a relatively more advanced, high-efficiency and energy-saving gravel sand equipment in the world, its performance has reached the international leading level.

Unique structure

1. Good energy saving effect MBS type rod mill energy-saving effect is higher than traditional grinding machine about 50% when it works.

2. Wide application range MBS type rod mill can be used in refractory materials, chemical industry, metallurgy, highways, railways and glass industry as well as on the grinding operation which has higher requirement of finished products uniformity, it can also be used in construction sand production industry.

Easy operation

The rod Mill has dry and wet two forms to choose from, users can choose according to own actual situation. The rod mill is named after its grinding media-steel rod. MBS type rod mill researched and developed by HXJQ adopts advanced production technology, combined with the actual production of grinding materials, and coupled with high-quality grinding body, change the traditional surface contact to line contact, so that get a more uniform product particle and higher yield.