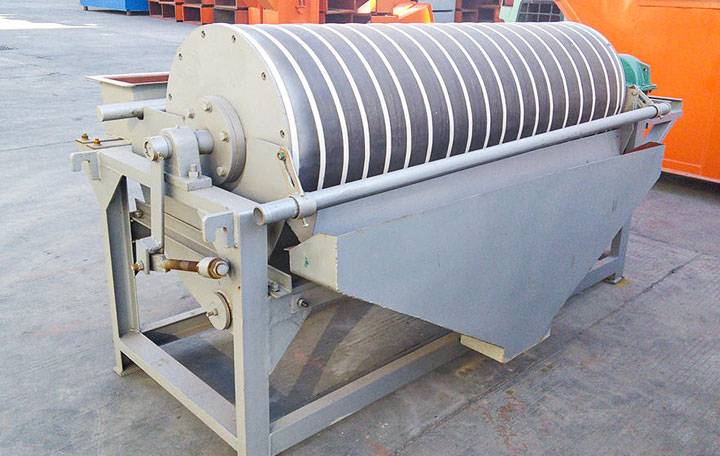

Magnetic separator is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials. It is also used for iron removing operations of coal, non-metallic minerals, building materials and other materials.

Unique structure

1. Reasonable structure, stable performance, and advanced design.

2. Advanced and reasonable process structure, and the combination of strong magnetic separation with anion anti-flotation are conducive to the realize the complementary advantages of the process.

3. The wearing parts are made of high-quality wear-resistant parts, making the equipment less wearing in the process of production and greatly extending the service life.

Easy operation

The magnetic separator produced by our company can be divided dry and wet magnetic separator according to different way of work. And we can provide downstream, semi-countercurrent, countercurrent, and other models of machine according to customers’ needs. Magnetic separator can separate materials with different magnetism, is one of the most widely used and versatile equipments in the industry. The two major factors to affect the magnetic separation is the feeding particle size of magnetic separation and pulp density.