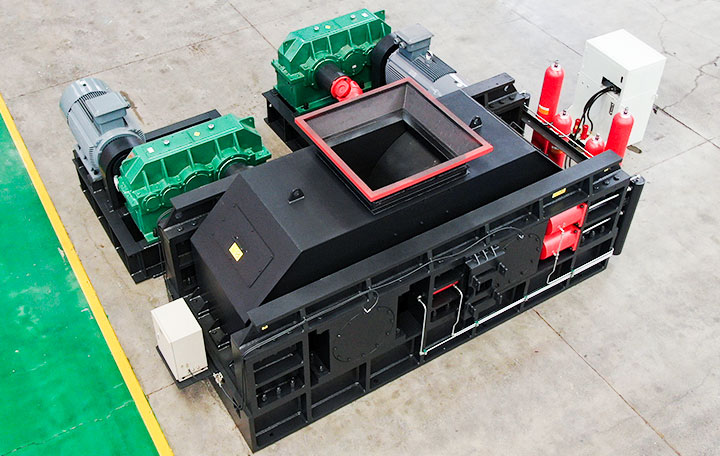

The hydraulic roller crusher is a new type of roller crusher that combines various advanced technologies. It has reasonable structure, advanced performance and powerful functions. Through excellent electromechanical and hydraulic integration design, the equipment can operate continuously, stably and reliably. In aggregate and grinding systems, it can generally increase the output by 30% - 40% and reduce the total energy consumption by 20% - 30%. It can finely crush materials of various hardness In mineral processing, chemical industry, refractory, stone processing, building materials and other industries.

Heavy thickened roller skin is adopted, with advanced materials, reasonable structure, wear resistance and impact resistance. The service life of parts is greatly extended with automatic lubrication device;

The equipment is equipped with an automatic control system, which is compact in structure, stable in operation, efficient and energy-saving. Compared with other crushing systems with the same performance, it can significantly reduce investment and usecosts, and has unparalleled advantages;

Keep the roller skin gap between 1-40mm stablely by hydraulic adjustment;

It is equipped with overload protection. When the unbreakable objects enter between the rollers, the rollers automatically give way and automatically recover to the set clearance.