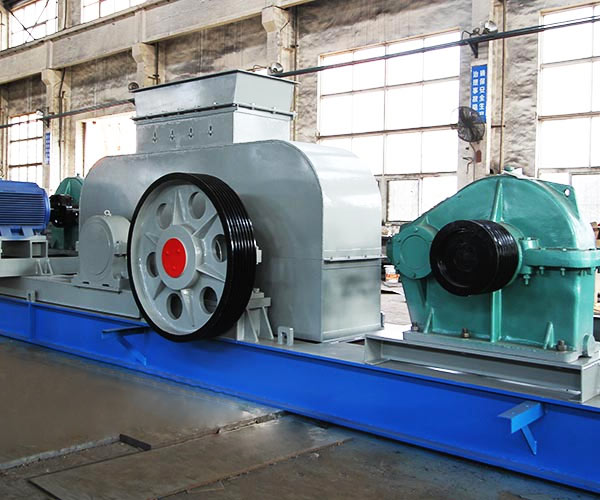

Roller Crusher

Feeding size:≤30mm

Production Capacity: 5-110t/h

Warranty:12 Months

Applied Materials:Pebbles, Granite, Basalt, Iron Ore, Limestone, Quartzite, Diabase, Construction Waste, Iron Ore, Gold Ore

Roller crusher is an universal crushing equipment developed by Hongxing machinery, which can not only used for coarse crushing but also can be used for fine crushing. Roller crusher is widely used to crush medium and high-hardness materials in metallurgy, building materials, refractories and other industries. In addition, 2PG 700×400-type roller crusher is the best choice to produce river pebble sand.

Outstanding Advantages:

Environmental protection, low noise: Roller crusher has solid structure, operation stable and reliable, which can reduce noise pollution and have an environmental protection effect.

High production efficiency, large capacity: Finished products are in cubic shape with low needle-like content and no cracks. Particle size is small and improves product quality and efficiency.

High return on investment: Roller wear cycle is long, wear parts are all made of latest high-strength wear-resistant materials, so it can crush high-hardness materials. low loss and long service life can bring considerable economic benefits to customers.

Working Principle:

The main structure of gear transmission device is fixed roll, movable rolls, drive shaft, frame, chassis, shell, long gear shell and other parts. Machine power is transmitted by the triangular belt pulley on the motor, and then through a pair of intermediate deceleration gear, so that make fixed roll rotates. Then movable roller is driven by a pair of long gears on the other end of the fixed roll. The two rollers forming relative movement to realize crushing effect.

Technical Data

| Roller diameter (mm) |

Input Size (mm) |

Processing capacity(t/h) |

| Ф400 | ≤25 | 5-10 |

| Ф600 | ≤25 | 10-20 |

| Ф700 | ≤25 | 15-30 |

| Ф800 | ≤25 | 20-40 |

| Ф1000 | ≤30 | 30-50 |

| Ф1200 | ≤30 | 40-70 |

| Ф1500 | ≤30 | 60-110 |

Get Quotation

Get Quotation Inquiry Online

Inquiry Online