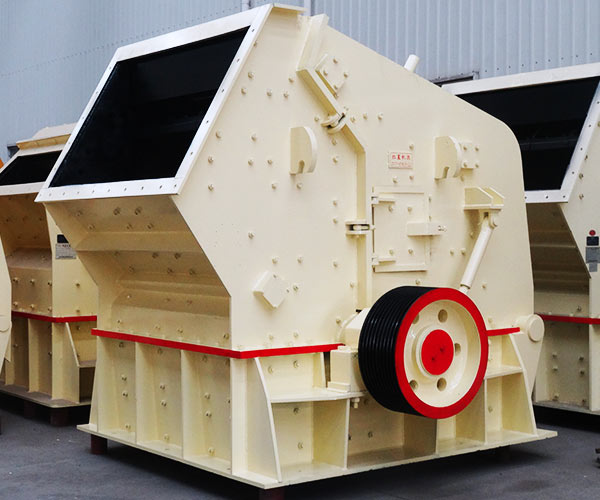

Impact Crusher

Feeding size:≤800mm

Production Capacity: 30-800t/h

Warranty:12 Months

Applied Materials: Iron ore, hematite, pyrrhotite, limonite, roasted ore, ilmenite, magnetite, copper ore, gold ore, coal, quartzite

This series impact crusher is one of the latest generation crushers developed by our company, which absorbs the advanced technology and combines with specific mining conditions of world sand industry. It adopts latest manufacturing technology and unique structural design. Its discharging size can be adjusted and crushing specification is diversified. Finished products shape is very good and all in cubic shape with no tension and cracks.

Advantages:

High efficiency and energy saving: Large feed inlet, high crushing chamber, applicable to high-hardness and large-size materials, and the finished product with less powder.

Good particle size: gap between impact plate and plate hammer can be conveniently adjusted to effectively control the particle size.

Unique structure: Compact structure, strong rigidity and large rotor inertia.

Comprehensive benefits: High chromium plate hammer, impact resistance and abrasion resistance and strong impact force.

Working Principle:

Impact crusher uses impact energy to crush material. When impact crusher works, the rotor rotates at high speed under the motor drive, the materials enter plate hammer working area and are crushed through the crushing with plate hammer on rotor. Then the materials are thrown to impact device and bounce back to the plate hammer working area and be crushed again. This process repeats, the materials are crushed from big to small through entering first, second and third crushing chamber, then finished products are discharged until the materials are crushed into desired size.

Technical Data

Impact Crusher

| Model | Feed Opening (mm) | Max.Feeding Size (mm) | Capacity (t/h) |

| PF-1007 | 400×730 | 300 | 30-70 |

| PF-1010 | 400×1080 | 350 | 50-90 |

| PF-1210 | 400×1080 | 350 | 70-130 |

| PF-1214 | 400×1430 | 350 | 80-180 |

| PF-1315 | 860×1520 | 500 | 100-280 |

| PF-1320 | 993×20000 | 500 | 140-380 |

| PF-1520 | 830×2040 | 700 | 200-550 |

| PF-1820 | 1260×2040 | 800 | 300-800 |

HD German Impact Crusher

| Rotor (mm) |

Discharging (mm) |

Capacity (t/h) |

|

| -150MPa | -350MPa | ||

| Φ1040×1000 | 400 | 200 | 90-190 |

| Φ1300×1500 | 700 | 300 | 180~280 |

| Φ1500×2000 | 1000 | 400 | 350~500 |

| Φ1650×2500 | 1300 | 500 | 500~670 |

CI Series Impact Crusher

| Model | Maximum Feeding Size (mm) | Capacity(t/h) |

| CI1110 | 250 | 60-210 |

| CI1213 | 300 | 80-280 |

| CI1316 | 300 | 100-350 |

| CI1521 | 350 | 200-600 |

| Model | Maximum Feeding Size (mm) | Capacity(t/h) |

| CI1313 | 600 | 100-480 |

| CI1415 | 600 | 120-600 |

| CI1620 | 800 | 220-900 |

| CI2023 | 800 | 200-2000 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

HX Impact Crusher

HX Series Counterattack Break Secondary Counterattack Break (Fine Break)

Containing hopper(t)

| Model | Maximum Feeding Size(mm) | Power(kw) | Processing capacity(t/h) |

| HX100S | 300 | 160 | 60-210 |

| HX120S | 350 | 200 | 80-300 |

| HX140S | 350 | 400 | 150-700 |

HX Series Counter-break Primary Counter-break (Coarse Break) Applicable to Construction Waste Crushing

| Model | Maximum Feeding Size(mm) | Power(kw) | Processing capacity(t/h) |

| HX100P | 600 | 160 | 60-210 |

| HX120P | 900 | 200 | 80-400 |

| HX140P | 1000 | 315 | 200-700 |

Get Quotation

Get Quotation Inquiry Online

Inquiry Online