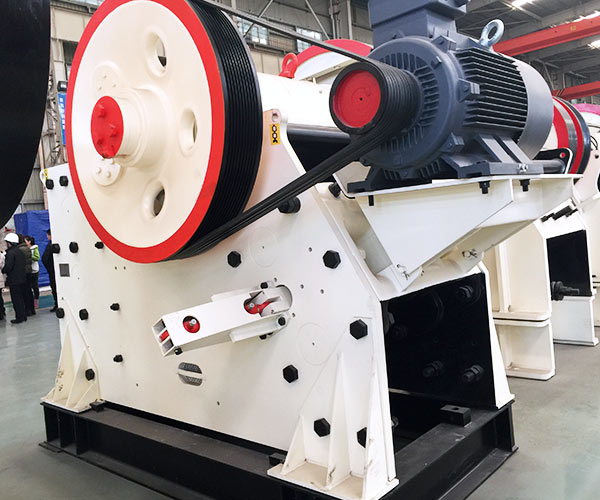

CJ Series Jaw crusher

Feeding Granularity: 120-1500mm

Production Capacity: 1-2200t/h

Feed Opening:150×250-1600×2100mm

Handling Materials: Pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, iron ore, coal gangue, construction waste, ferrosilicon, basalt, sandstone, rocks, ore, glass, cement clinker and some metal.

CJ Series Jaw crusher is an excellent performance jaw crusher, which is developed by Henan Hongxing Mining Machinery Co., Ltd. according to customer market needs. Compared with the traditional jaw crusher, it has great improvement in movement parameters, structure and adjusting methods, etc. CJ Series Jaw Crusher occupies a small space and has bigger crushing ratio, at the same time its operation more stable. It has more advantages in transportation, installation, maintenance and adjustment. Especially it is suitable for fixed crushing production line and mobile crushing station.

Advantages:

Non-welded detachable rack: cylindrical pin connects rack side plate, front wall plate and rear beam. Bolt fastening, overcome the stress concentration shortage that welding frame easily produced, which makes rack more solid and reliable. Detachable structure is convenient for transportation and installation, especially for underground installation and transportation.

Optimize motion parameters: Excellent motion parameters, so that the materials begin to be break in the upper part of the crushing cavity. Crushing stroke and ratio is greater in the lower part.

Steel brackets: Jaw crusher adopts high-strength steel as brackets, it will bend deformation when crusher overload to protect the crusher key components from damage. Comparing with the traditional cast iron bracket, Steel bracket weight is lighter. And the replacement is easier, which avoid broken cast iron brackets falls and damage conveyor.

Integrated motor base structure and overall steel frame base: Integrated motor base and mainframe structure makes installation more convenient and saves space. The whole machine is placed on the steel frame base, damping pad connect mainframe and base, which has small impact on the foundation.

Technical Data

| Model | Max.feeding size (mm) |

Processing capacity (t/h) |

| PE-150×250 | 125 | 1-3 |

| PE-200×300 | 180 | 2-6 |

| PE-200×350 | 180 | 3-10 |

| PE-250×400 | 210 | 5-21 |

| PE-400×600 | 340 | 16-64 |

| PE-500×750 | 425 | 40-110 |

| PE-600×750 | 500 | 80-240 |

| PE-600×900 | 500 | 50-160 |

| PE-750×1060 | 630 | 110-320 |

| PE-800×1060 | 640 | 130-330 |

| PE-830×1060 | 650 | 150-336 |

| PE-870×1060 | 660 | 190-336 |

| PE-900×1060 | 685 | 230-390 |

| PE-900×1200 | 750 | 220-380 |

| PE-1000×1200 | 850 | 315-500 |

| PE-1200×1500 | 1020 | 400-800 |

| PE-1500×1800 | 1200 | 500-1000 |

| PEX-150×750 | 120 | 8-25 |

| PEX-250×750 | 210 | 13-35 |

| PEX-250×1000 | 210 | 16-52 |

| PEX-250×1200 | 210 | 20-61 |

| PEX-300×1300 | 250 | 16-105 |

Get Quotation

Get Quotation Inquiry Online

Inquiry Online